A Tamworth specialist manufacturer for the likes of Rolls Royce is looking to expand its team after new quality inspection software installed with the help of Made Smarter West Midlands has boosted its productivity.

Brown and Holmes specialise in producing work holding and machining solutions for companies in many industries including automotive, aerospace, and construction.

While the business had been successful, it found itself in a tough spot when a large client needed highly detailed quality control reports with every part that was sent to it.

Although Brown and Holmes could produce the reports, it was a time-consuming process that meant its 60 staff could not focus on other projects.

Made Smarter worked with Brown and Holmes to identify software that could dramatically speed up this process and increase productivity as a result.

It helped the company apply for a match-funded grant to pay for the software, which is already making a significant difference.

Kevin Ward, joint managing director of Brown and Holmes, said: “We’ve gone from having around £500,000 worth of work for this client to potentially around £1.3 million this year thanks to this software – close to tripling our productivity.

“Choosing and paying for the software was far easier thanks to Made Smarter’s support. We’re

now in a strong position going into 2023 and this boost will enable us to look at expanding the business.”

I had an idea about the kinds of software that could work for us, but having experts from Made Smarter helping you make an informed decision was invaluable.

Kevin Ward, Joint Managing Director at Brown & Holmes

Brown and Holmes has been established since 1939, and has produced all sorts of components and solutions for a great range of customers all over the world, including tooling for Rolls Royce jet engines.

Its own machines on its two sites on the Lichfield Road Industrial Estate are state-of-the-art and can handle all sorts of requests from its clients.

However, a request from a newer client for detailed quality reports with each part produced a headache for its staff. Producing just one of these reports for a part took several hours, as much of the data had to be manually collated and entered before the part could be shipped.

Kevin said: “This was a clear bottleneck for us that we didn’t really foresee – it hampered our ability to deliver parts quickly to the client and meant our manpower was stretched.

“We needed to find a solution to maximise the work we could perform for this client, and we thought new software might be the way to do it.”

While looking online for potential solutions, Kevin came across the Made Smarter website and saw how the scheme helped many businesses like his solve problems related to productivity.

Kevin made an enquiry through the website, and Made Smarter Digital Transformation Specialist for Stoke-on-Trent and Staffordshire Tim Kirby then contacted Kevin to arrange a visit.

He was joined by Michael Stevens and Shai Tailor of Made Smarter’s partners the Manufacturing Technology Centre (MTC), who helped advise Kevin on the most appropriate software for Brown and Holmes.

Kevin said: “I had an idea about the kinds of software that could work for us, but having experts from Made Smarter helping you make an informed decision was invaluable.

“The products are sometimes highly complex and cost a lot of money, so we wanted to have

that reassurance that we were making the right decision.”

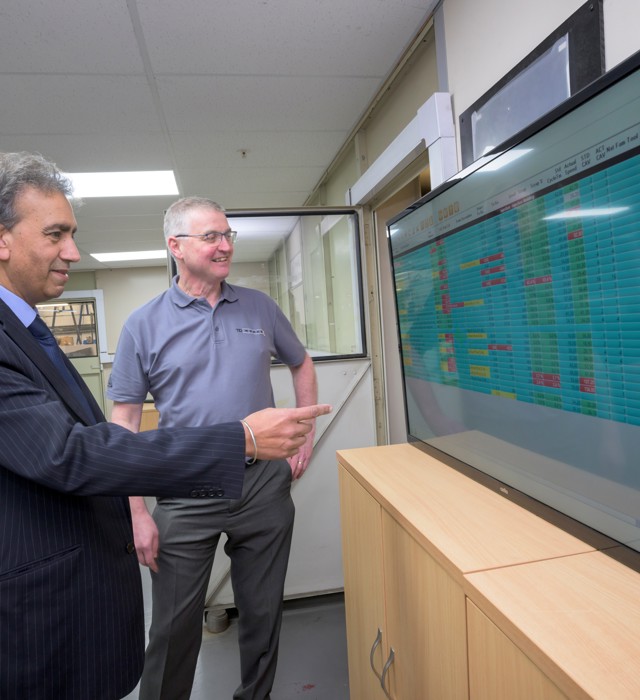

After advice from Made Smarter, Kevin opted for a Sempre quality management system which can extract measurements and other key data from parts and technical drawings and automatically incorporate them into a report.

It also enables companies to collate data from multiple machines at the same time, which drastically reduced man-hours. Made Smarter also helped Brown and Holmes apply for a match-funded grant worth around £16,600 to pay for the software.

Kevin said: “The Sempre system looked like the best solution for us – all of the problems we were facing with this client could be dealt with if we had this software integrated into our business.

“We really appreciated Made Smarter helping us apply for the match-funded grant. They advised us on the correct wording to use and made the process incredibly easy. It also meant the costs of purchasing the software was significantly softened, which was a great help.”

Tim added: “It’s often the case that the businesses we visit know the kind of solution they are after, but need that bit of reassurance that they are making the right decision.

“We were able to show Brown and Holmes that the Sempre software was best for their business after discussing their issues with them, and our guidance meant it received the grant money promptly.”

And Michael added: “There are a lot of different kinds of inspection software available for manufacturers on the market, so for those businesses that aren’t familiar with them, it can be a daunting prospect to make a decision.

“But after Brown and Holmes went with our recommendations, the software is already making a big impact on its productivity.”

After installation of the new system, producing quality inspection reports went from a 13-hour job to one that took barely an hour. It meant Brown and Holmes could ship completed parts at a much higher rate than it could before, dramatically increasing turnover from that client.

Kevin added: “The return on investment has been practically immediate – the software has completely eliminated the bottleneck we once had.

“Producing highly-detailed quality inspection reports is now a simple process, and not only has given us scope to offer this service to existing and new clients, it means our staff now have more capacity to manufacture products for customers which means we can take on more work.”

Tim added: “It’s fantastic to see just how much of an impact the software is having on Brown and Holmes. Clearing bottlenecks can be very difficult for SMEs without external support and advice, so we’re really pleased to have made a positive difference and to have helped Brown and Holmes take that next step forward.”

Now that capacity has increased, Kevin is looking at bringing in more staff to enable the company to deliver more work.

“We’re definitely in a position to expand the business, which is brilliant considering the wider market conditions at the moment,” Kevin added.

“If we can get further staff into the business, we’ll be able to offer more work to clients and boost our revenue.

“This wouldn’t have been possible without the installation of the new quality inspection system.

“Without Made Smarter’s support in helping us find the right software and applying for a grant, it would have been very difficult to have removed that bottleneck by ourselves. We just didn’t have the time, capital or know-how readily available.

“But the future is looking bright for us. I’d encourage any business in a similar position to us to contact Made Smarter – they’ve helped us enormously.”