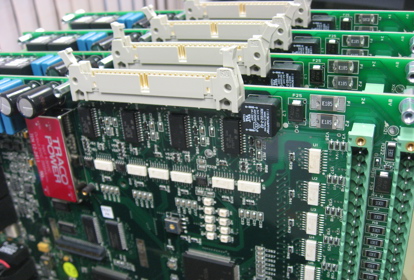

Quartz TSL (Technical Services Ltd) is an industry leading manufacturer and developer of printed circuit boards (PCBs) and electronic sub-contract manufacturing, offering peace of mind for their clients. With full traceability, robust, and continually monitored accreditations, Quartz TSL values building enduring partnerships with customers and offering ground-breaking products.

Established in 1987 by Brian Mousley, Quartz TSL has consistently evolved, broadening its range of services to adapt to the ever-changing needs of its customers. Today, under the leadership of Managing Directors Neil Mousley and Project Director Paul Mousley, the company remains dedicated to delivering exceptional manufacturing solutions, guided by a vision of fostering long-term partnerships and promoting innovation in electronic manufacturing.

Paul Mousley effectively captures the essence of the company's ethos, stating, "We combined our years of manufacturing experience and technical knowhow to create innovative solutions to meet our customer's needs.

What we deliver is a one-stop shop service, we can offer the full products from PCB manufacture & assembly all the way through to wiring and full assembly testing.

What set us apart is out high standard and product quality. We deliver a premium product but with that, our customers have peace of mind the equipment made by us should just keep working continually. Our quality guarantees that you don't need to worry about costly repairs or downtime at any point down the line."

The difference with Made Smarter is it got me thinking more - I actually needed to sit back and review the business. We had some processes in place that almost organically happened but weren’t necessarily the most effective and productive way of doing things.

The Made Smarter programme just seemed to ask more probing questions of how we approached our processes. The programme got us thinking more proactively and questioning ourselves about how we approached many aspects of our business in a good way.

Paul Mousley, Project Director

Despite their dedication to quality, Quartz TSL faced a significant challenge in modernising their technological infrastructure.

With hardworking machinery at the end of their lifecycles which may compromise efficiency and productivity, the need for a comprehensive upgrade and technological leap forward became obvious.

Finding funding and investment in the fast-changing manufacturing industry was challenging.

With growth initiatives relying on self-financed machinery acquisitions, smart spending became crucial, ensuring everything was considered, cost-effective and beneficial to the business.

With the support from Made Smarter East Midlands, Quartz TSL utilised grant funding to purchase a new surface mount AOI (Automatic Optimal Inspection) machine. This advanced equipment allows them to inspect electronic assemblies quickly and more efficiently. The AOI machine allowed much bigger printed circuit boards to be inspected.

With faster and superior inspection software and algorithms catching any errors and improving quality levels at a faster pace.

Quartz TSL started on a transformative journey, leveraging the resources and expertise provided by Made Smarter to enhance their operations. Thorough roadmap planning and strategic assessments of internal processes helped them identify areas for improvement and optimisation. Made Smarter’s guidance facilitated an internal shift, prompting Quartz TSL to adopt new technologies and methodologies to streamline operations and maximise efficiency.

The introduction of digital solutions and process improvements has brought significant advantages to Quartz TSL.

They’ve experienced up to three times faster production rates, which has greatly boosted productivity and efficiency whilst also reducing workload and errors.

By embracing advanced software and automation, they’ve achieved remarkable levels of efficiency and accuracy in manufacturing and assembling PCBs. Additionally, the use of sophisticated inspection systems has enabled Quartz TSL to identify and fix defects with precision, ensuring that their customers receive flawless products.

Looking ahead, Quartz TSL is set up for ongoing success, driven by their dedication to innovation and continuous improvement. With new technologies expanding their reach into diverse markets, they’re ready for continued growth.

Paul will be participating in Made Smarter’s Digital Leadership Transformation Course later this year, delivered by Loughborough University. This will help further his understanding of what is possible to improve and streamline the business. The course will also provide a great opportunity for Paul to share knowledge and learn from other manufacturers about what they are doing. Quartz TSL’s journey demonstrates a consistent commitment to excellence, innovation, and sustainable growth, establishing their position as a premium product provider in the electronic manufacturing industry.

With a clear vision for the future and ongoing loyalty to their fundamental principles, Quartz TSL is ready to shape the landscape of electronic manufacturing for years to come.