Harnessing technologies to optimise the design and execution of current and future factories.

- Manufacturing process and operations

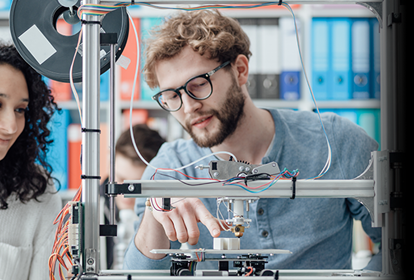

- Use of robotics or additive manufacturing to accelerate processes

- Dynamic, real time production planning and scheduling

- Digital twins of facilities & processes to optimise future designs or current state

- Real time/in process quality monitoring and process optimisation

- Digital track and trace systems

- Asset management optimisation

- Use of robotics and autonomous systems to improve productivity or worker safety

- Connected worker – augmented & virtual solutions for task assistance, training or safety.