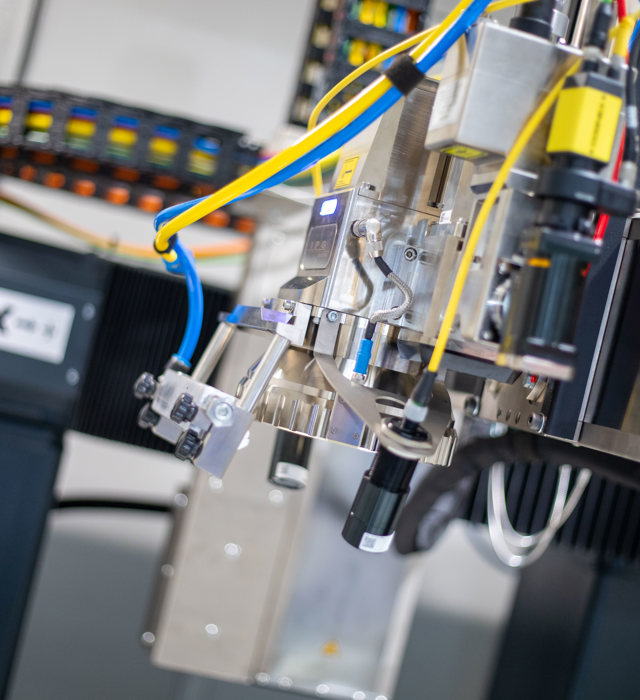

Established in 2016, iPac is a family-owned and managed business producing thermoformed plastic packaging for the food and pharmaceutical industries.

Operating across two sites in Gateshead and County Durham, the company has grown rapidly in the past eight years and now employs more than 80 employees.

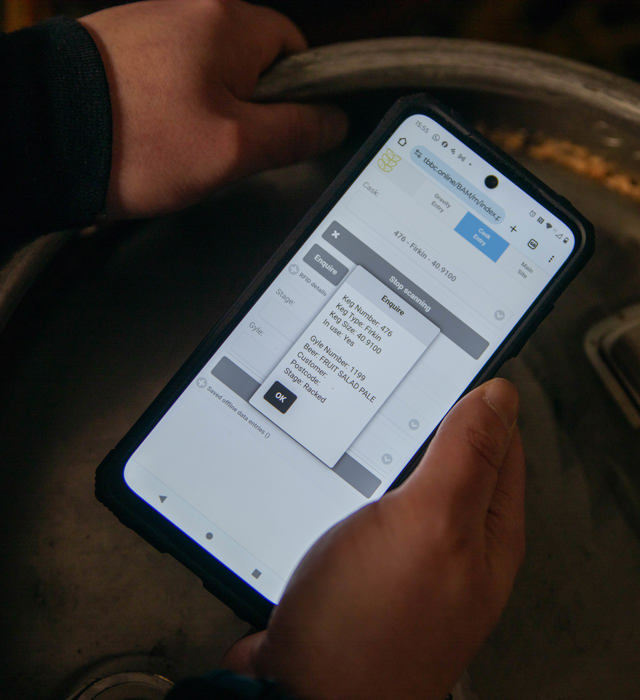

iPac worked with Made Smarter to integrate a new Warehouse Management System (WMS) into its existing Enterprise Resource Planning (ERP) system. The new WMS - which includes barcoding and traceability - has significantly enhanced stock accuracy and productivity across the business. It has also improved communication across departments and provided the foundations for further growth.

Case Study - iPacThe costs for implementing new digital solutions can be quite scary, but as a result of working with Made Smarter we’ve been able create processes and systems that are scalable. As a result we’re continuing to grow with plans afoot to bring in new business and hire new staff.

Dean Allsopp, Finance Director at iPac

Relying on a manual warehouse management system with thousands of lines of data, iPac was struggling with stock accuracy, as well as the physical location of stock across its two sites. Dean Allsopp, Finance Director at iPac, knew the current system was open to human error and had no simplicity in its traceability. “The price of plastic changes can be very volatile, so if you’ve understocked at a lower price point, it can have a real financial impact on the business.”

Working with Made Smarter, iPac was able to access grant funding to integrate a WMS system into its existing ERP system, providing barcoded locations of every area across its two sites.

“We went from basic excel to having the process built into our system. The WMS automates all stock related transactions, ensuring the right stock is in the right place at the right time. This immediately reduced the potential for overstocking and understocking issues.

“The scanners provide traceability at every level of the business, so if we need to, we can delve into the detail and see every stage of the process.”

Now, when the Sales Team place an order, the Warehouse Team instantly know exactly what to collect and where to find it. It provides much better stock accuracy and has improved productivity.

“We’ve been using it for three months now and it feels like we’ve been using it forever. After some initial trepidation, everyone in the business is fully on board and really sees the benefits.”

The integration and alignment of departments within the business is seen as one of the biggest benefits of working with Made Smarter. “After about two or three weeks it was like a light bulb came on and everyone could see how everyone’s roles were interlinked. It’s really helped integrate the teams, which was unexpected, but a really nice thing.”

Improved accuracy has delivered costs savings, particularly around stock levels. And greater productivity through the speeding up of tasks has opened up further business growth for iPac.

“The costs for implementing new digital solutions can be quite scary, but as a result of working with Made Smarter we’ve been able create processes and systems that are scalable. As a result we’re continuing to grow with plans afoot to bring in new business and hire new staff.”

The next tech-driven project for iPac is to improve overall equipment effectiveness (OEE).

“Getting those gains in our production process and improving speed, productivity and accuracy are key for the future success of the business. If we can run our machines at 85% rather than 80%, that brings huge benefits. Staying up-to-date with the latest technology and delivering continuous improvement will be vital in maintaining our growth and competitiveness.

“It’s also really important for us that we retain that family culture across the business and integrate people into it. We want to continue exploring new opportunities and technologies so we can drive further expansion and innovation across the company.”