The leading North East business worked with Made Smarter to see how digital technology could be used to address some of the company’s biggest organisational challenges.

Based in Peterlee, Country Durham, Alexander Battery Technologies specialises in the design and manufacture of bespoke portable power, batteries, and charging solutions across diverse sectors including medical, safety, electrified vehicles, and robotics.

Collaborating with Made Smarter, the company embarked on a journey to leverage digital technology to enhance its operations and meet evolving industry demands. Alexander Battery Technologies is committed to driving growth and embracing the advancements of Industry 5.0.

Case Study - Alexander Battery TechnologiesEngaging with Made Smarter helped open our eyes to the benefits of digital technology in the organisation.

Brett Ramshaw, Production Manager at Alexander Battery Technologies

As a rapidly growing company, Alexander Battery Technologies encountered operational challenges in three key areas: traceability, security, and automation.

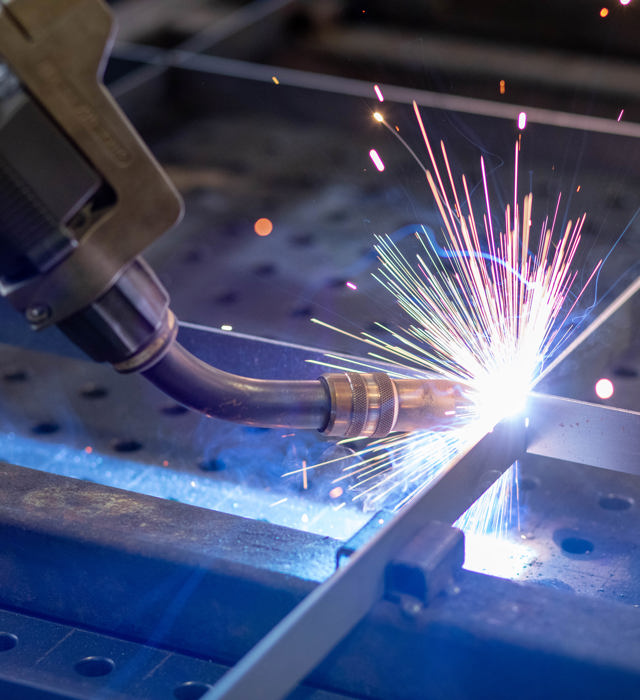

Prior to the company’s factory expansion, access to projects and laboratories was increasing the risk of contamination and impacting productivity within the business. Despite introducing semi-automated equipment, such as ultrasonic and resistance welders, Alexander Battery Technologies still lacked a fully automated system.

Brett Ramshaw, Production Manager at Alexander Battery Technologies, said: “In previous years, a lot of our system processes were manual, resulting in prolonged completion times. We also recognized that we could reduce the risk of negative impact to project timelines by introducing a security system on site.”

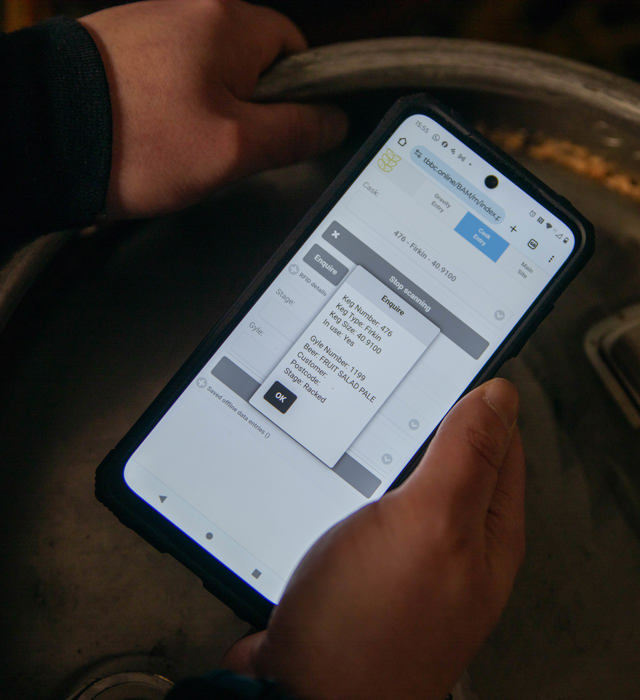

The company invested in a digital security system to regulate laboratory access and implemented an Enterprise Resource Planning (ERP) system for enhanced traceability. The adoption of cutting-edge technology - such as the world’s first EV Flex advanced laser welder - marked a significant leap towards full automation.

Brett said: “Because Made Smarter Adoption North East was able to share examples of positive case studies and educate us on the real benefits of various digital solutions, we began to introduce some of our own and have seen many positives already.

“Engaging with Made Smarter helped open our eyes to the benefits of digital technology in the organisation.”

Since taking part in Made Smarter, Alexander Battery Technologies has seen tangible improvements in productivity, a strengthened security infrastructure, and a notable uplift in performance.

Brett continued: “Made Smarter provided us with good, reliable advice and helped source funding, which in-turn helped us address some of our biggest challenges.”

Alexander Battery Technologies is committed to innovation and continuous improvement. The company plans to further automate operations and prioritise staff upskilling; helping to lead the charge in embracing Industry 5.0.

By aligning with the evolving needs of digital-dependent industries, Alexander Battery Technologies is solidifying its position as a trailblazer in the manufacturing sector. Through strategic digital integration and a steadfast commitment to innovation, the company is not only addressing current challenges, but also paving the way for sustained growth.

Brett said: “Some of our clients are heavily reliant on digital technology, particularly in industries like electrification and robotics, so by embracing smart technologies ourselves, we’re demonstrating our committed to industry 5.0.

“A lot of manufacturing technologies are still in their infancy, and we want to be part of their development and evolution both as a provider and supplier.”