In our first article, we introduced you to 8 highly innovative businesses exhibiting on Made Smarter Innovation Alley, running through the heart of Smart Factory Expo at Digital Manufacturing week, later this month.

Let’s meet 8 more confirmed exhibitors, all of whom have Industrial Digital Technologies that align with the Made Smarter Innovation programme, developed to make your manufacturing process more connected, more visible, and more accessible. These digital technologies include Additive Manufacturing, Blockchain, Data Analytics, Artificial intelligence and Machine learning technologies, Immersive Technologies such as VR and AR, Industrial Internet of Things (IIoT), Robotics, and Automation and Sensors.

Measurable.energy is a UK based startup company with a mission to create energy efficient workplaces that inspire people to positively impact energy consumption and environmental sustainability. It uses Machine Learning technology, through a bespoke plug socket, to identify and eliminate small power-wasted energy from commercial buildings, reducing energy consumption and CO2 emissions.

Adam Wright, Head of Commercial at Measurable.energy, said “ Manufacturing businesses have a variety of uses for plug sockets. There is a real opportunity for measurable.energy to bring significant savings for manufacturers through reductions in electricity bills and CO2 emissions.

Established in 2018, Arbor Standard specialises in providing one-stop 5G Cloud XR solutions to the global enterprise sectors by integrating leading technologies and market insights. It uses a XR interaction, pioneered by the company, in real-time and digital transformation solutions to improve remote interaction for industrial enterprises, through higher-density information delivery and with higher-quality interactive experience.

Its product, Arbor 3D® Work, provides an immersive upgrade of management workflow with 360° live streaming, cloud conferencing and workspace to allow stakeholders to conduct inspection, operation, auditing, and training remotely.

Director Kai Lam said, “We are attending Innovation Alley to showcase our solution to the manufacturing sector and find potential partners and clients who are interested in digitalised remote management workflow as a smart factory solution to reduce travelling cost, increase productivity and reduce carbon emissions.”

Agave Networks helps manufacturers to take a step further in their net-zero objectives by relocating their excess products and materials to the best user in the market.

Using AI and ML algorithms, the Agave Networks online platform locates excess products in the users' inventory, including raw materials and byproducts, to later match them with businesses in the area that could reuse them.

Daniel Byrd, CEO of Agave Networks said, “We are looking to widen our network of partners and customers at Smart Factory Expo and have conversations to better understand their needs and drivers for their net-zero waste objectives.”

Unitive Design and Analysis Ltd

Unitive Design provides leading-edge intelligent sensing and imaging technologies which capture critical data for the improvement of efficiency in manufacturing processes and across the supply chain.

Business Development Manager, Pauline Brown said, “Sensors are getting much smarter. Through the strategic implementation of intelligent sensors across production, storage and transport environments we can capture digitalised real-time data which has a direct impact on strategic and tactical decisions. Visibility across the supply chain is becoming even more important. By implementing smart sensors and working closely with the supply chain and machine learning experts we are helping manufacturers to see the benefits of digitalisation.

Our participation in Innovation Alley is a fantastic way to meet people in the industry who are seeking improvements in quality and efficiency and to raise our profile in the manufacturing industry.”

FluidMS develop easy to use and affordable digital sensing solutions to reduce cost and risk in the workplace.

Focusing on Machine, Operator and Process Health our innovative approach is affordable for the smallest of SMEs and cost effective for larger blue-chip manufacturers.

Our solutions are helping early adopters reduce cost and risk by:

- understanding health exposure risks to employees and plan to e.g., improve air quality.

- providing better insight into machine health for more effective maintenance interventions.

- realising non-productive periods for better scheduling and reduced energy costs.

Data securely flows from Edge to Cloud via our Cellular Gateway for display on our Web App, built from the ground up in Microsoft Azure.

Steve Thompson, MD said “We deliver new insight to those who need it to make informed decisions for a cleaner, leaner, safer and smarter working environment.”

Augmented Solutions deliver augmented reality solutions to UK and global businesses in the areas of asset management and additive manufacture.

MD Mike Griffin said, “We are really looking forward to Innovation Alley to gather market intelligence, develop new partners and understand better the routes to market for our goods and services.”

AI Automation provides bespoke, turnkey automation solutions, specialising in camera inspection and robotic applications for the manufacturing industry.

Sales Manager Jonathan Whittam said, “We are looking forward to Innovation Alley as we want to learn and remain up-to-date with the best technology available that will help solve our customers’ problems. We are also looking to connect with potential customers and increase our brand awareness.”

Motion Robotics is developing collaborative AI driven robotics for aerial drone cargo and drone handling. The robots are manufactured using state of the art manufacturing techniques including additive manufacturing and 5 axis CNC machining.

Director Denis Majoe said, “We are exhibiting our robotics technology on Innovation Alley to widen awareness of what we do and to build partnerships across UK manufacturing.”

iov42 provides novel distributed ledger technology (permissioned), for enterprise and government use. They have built operational digital product passports for different manufacturing sectors - steel (with Tata Steel) and timber (used by numerous UK, European and SE Asian companies (large & small)). They are also investigating its suitability for other manufacturing organisations and commodities.

Anna Roberts from iov42 said, “We are exhibiting on Innovation Alley to learn about other relevant technologies, engage with manufacturing leaders and innovators, better understand market readiness for technologies like ours and build brand awareness of iov42.”

Get Involved

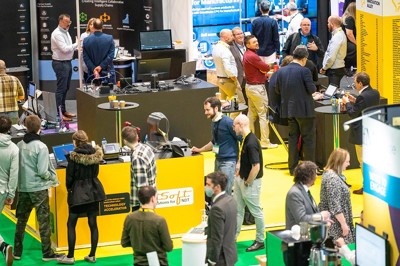

Made Smarter Innovation Alley is the UK’s primary showcase of new, disruptive, innovative digital technologies for the manufacturing sector, taking place in Liverpool on 16 and 17 November 2022. Innovate UK funds 50 of the UK’s most innovative businesses to exhibit on Innovation Alley each year. Supported by Innovate UK KTN, this is a great opportunity for startups and scale-ups to:

- Reach the right audiences (over 5,000 manufacturers attend Smart Factory Expo every year)

- Build partnerships that can enhance digital technology solutions to become much more appealing to larger manufacturing customers

- Market test new ideas and solutions with the people who would be using them

There are only a few fully funded places left on Innovation Alley 2022. If you have an innovative digital technology that will transform manufacturing, sign up at https://www.digital-manufacturing-week.com/innovation-alley-funded-stand or speak to Mat Wasley (matthew.wasley@ktn-uk.org) at Innovate UK KTN to find out more.