A leading manufacturer of bespoke testing machines that push high-tech components to their limits is rolling out a new lab management system to power its next stage of growth, after Made Smarter West Midlands helped fund the upgrade.

Darvick, founded by husband and wife Darren and Vicki Wilkes, works with clients in aerospace, nuclear engineering, transport, and more, to design and build individual machines that test new materials and components for applications such as lightweighting jet engines under extreme environmental conditions, including elevated temperature, pressure and super-heated steam, to test their capabilities in conditions that represent their real world use.

The business, based in Brierley Hill in the Black Country, had grown from a tight-knit team of four to a team of 10, but was hitting a bottleneck due to its outdated methods for quality management and data processing from its testing.

After contacting Made Smarter to see what improvements could be made, Darvick applied for a grant of £17,000 to fund a new Laboratory Information Management System (LIMS), to keep better track of its quality management and testing data and improve productivity.

Now, the company is confident the new system will see productivity increase and improve the traceability of its tests.

Our new LIMS is exactly what we need to take Darvick to the next level, and Made Smarter’s informed advice helped us take the right steps to make it happen.

Vicki Wilkes, owner of Darvick

The machines Darvick builds for testing clients’ components are cutting-edge, requiring incredible engineering expertise to both design and build.

However, the company would record other information like testing data, order numbers, and contracts with basic software such as Excel, Word, and emails.

It meant a lot of time was wasted checking and verifying information before a test could be fulfilled properly for a client.

Vicki said: “Being a small business, it was difficult to find the time to search for a new system while also keeping the company going.

“However, when we started to get to a team of ten and our workload hit a certain point, we knew we had to modernise our systems and record-keeping to reflect the cutting-edge nature of our work.

“Certain processes just began to take too long and we hit a point where modernisation was the only realistic way for us to grow.”

Through membership of several business organisations in Dudley and the Black Country, such as Dudley Business Champions, and a strong network among like-minded companies, Vicki and Darren had heard of what Made Smarter West Midlands could provide for an SME like theirs.

Vicki decided to reach out to Made Smarter to get their advice and find out if the business was eligible for grant funding to help pay for potential improvements.

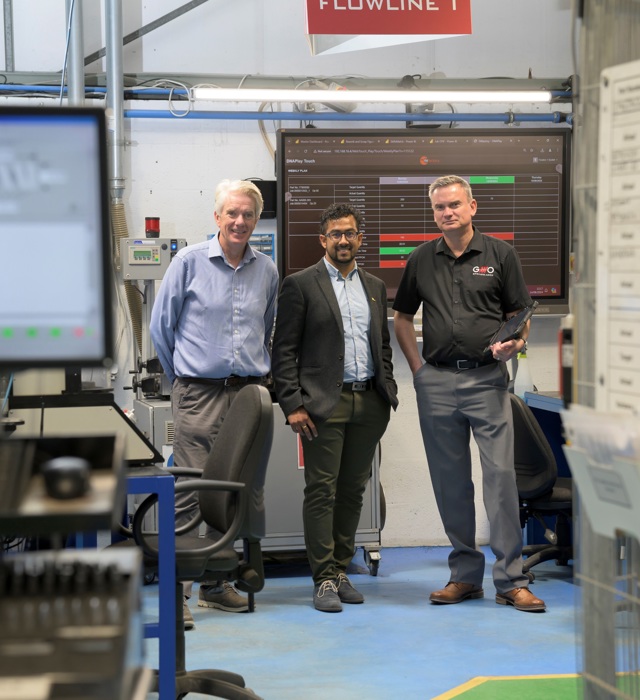

Jit Gatcha, Digital Transformation Specialist for the Black Country at Made Smarter West Midlands, visited Darren and Vicki alongside Denis Pelych, Digital Manufacturing Advisor at WMG, to talk through what solutions might be possible for Darvick.

Although the manufacturing side of Darvick’s business was identified as needing improvement, the testing side was found to be the biggest bottleneck, in terms of completing projects for clients.

Darvick was advised to adopt specialised software for managing the processes of R&D projects, known as laboratory information management systems or LIMS.

After evaluating several possible types, Darvick chose to adopt a LIMS called Xybion due to its flexibility and UK support.

Darvick was then guided through the application process for a £17,000 match-funded grant from Made Smarter to help pay for the costs of the software.

“With each test being different from the last, we needed software that could easily adapt to each one,” Vicki added.

“Xybion seemed to tick those boxes, so we decided to go for it.

“Having Made Smarter cover some of the costs through its grant was great. It reduced our initial outlay significantly and meant the decision to modernise was made so much easier.

“And WMG’s perspective on the right kind of software for our needs was very useful. We needed a fresh pair of eyes to look at what we were doing and reassure us that we were making the right decision.”

Denis added: “It was clear that Darvick needed to make its data capture systems as advanced as the machines it was building for its clients.

“While MRP systems were considered at first, we collectively decided that integrating an MRP across the business would mean Darvick would have to alter too many of its processes to fit the system.

“We found that a LIMS for its testing processes would present the biggest benefit to Darvick, so we advised Darren and Vicki to take that route.”

Xybion is now being implemented in Darvick’s laboratory testing, and Vicki is hopeful the software will make a lasting difference.

“Having Xybion in place is going to make such a difference to our productivity,” she said.

“Being able to seamlessly integrate all our data instead of relying on clunky methods of manually checking spreadsheets, documents and emails will have an immediate impact.

“But it will also massively improve the traceability of our tests. If a client needs something clarifying after a test, or if we need to double-check something, Xybion will make that process so much faster and more reliable.

“It also means that audits from accreditation body UKAS will be much simpler, thanks to the ease of presenting vital data from our testing.

“With our clients prizing safety and reliability above all else, it is vital that we are doing everything we can at our end to eliminate mistakes and provide certainty for our customers.”

Jit added: “Systems such as LIMS, ERPs and MRPs can all have massive impacts on SME manufacturers who haven’t used them before.

“In Darvick’s case, the workload of the team, alongside not really knowing the possibilities of these kinds of software, meant Vicki and Darren weren’t able to take that next step.

“However, as with many of the SMEs Made Smarter West Midlands has worked with, being able to speak with Darvick and find the right software solution for them – as well as providing grant funding – has removed such a restrictive bottleneck in their business.”

Darvick is hopeful it will be in a position to grow the team after fully implementing Xybion across its testing, and is considering further improvements to the business.

Efficiencies from Xybion may allow for investment in R&D into new machines to test materials at ultra-low temperatures, such as for liquid hydrogen OEMs and supply chains.

An MRP system to support the production of these new machines could follow.

“We’d love to recruit tech-savvy test lab apprentices into Darvick and get the next generation of staff into the business,” Vicki added.

“With Xybion in place, it will position our business as being forward-thinking and enable incredible innovation across a wide range of sectors, which we think is a great proposition to offer to new staff.

“If Xybion has the effect we think it will, it might lead us to develop even more cutting-edge machines, which is an exciting prospect.

“Our experience with Made Smarter has allowed us to think more widely about how we can improve our processes as well, which we perhaps only did before when we hit a roadblock in our growth.

“Finally, we are also considering taking on interns from the University of Warwick through Made Smarter’s internship programme. Having skilled and enthusiastic graduates in our business gives us another edge, and we might not have known about it were it not for Made Smarter.”