A family-run precision engineering and manufacturing business is heading in the right direction to future success after receiving grant funding from Made Smarter West Midlands.

D.A.R.L Engineering was set up in 2019 in Brindley Road on the Bayton Road Industrial Estate in Exhall, Coventry, and now makes crankshafts primarily for the motorsport industry.

The business doubled the size of its premises last year to deal with the increasing demand for its services, and it is on track to reach £1 million turnover in 2025 for the first time.

The company consists of husband and wife, Daren and Kim Lynam, as well as Daren’s two sons, Adam and Ryan, his brother Lee, Kim’s nephew Kieran Howe, CAD CAM manager Steve Abbott, Scott Palmer as engineer, apprentice Owen Parkes, and Emma Downes in finance and admin.

D.A.R.L Engineering, which counts NS85 Ltd among its customers, has invested in a second five-axis Digital CNC milling machine to build on its success after receiving a grant from Made Smarter West Midlands.

Director, Kim Lynam, said the business needed to link all its machines together digitally.

She said: “The Made Smarter West Midlands team was fantastic at highlighting the opportunities that were available to assist with our growth plans.

“Our order book is overflowing, which is a fantastic position to be in and we are now looking at further ways we can digitise the business.”

The Made Smarter West Midlands team was fantastic at highlighting the opportunities that were available to assist with our growth plans.

Kim Lynam, Director D.A.R.L Engineering

Our order book is overflowing, which is a fantastic position to be in and we are now looking at further ways we can digitise the business.

D.A.R.L Engineering was initially focused on general engineering work but since Covid-19, the business has switched to concentrate on Motorsport components and also designing and manufacturing crankshafts which required a great deal of investment.

A total investment of £500,000 was made which led to the business immediately increasing its output.

Demand continued to soar which meant an additional machine needed to be purchased to ensure growth didn’t stagnate.

Kim said: “When we initially switched to manufacturing crankshafts, we could make ten a month, but we knew we needed to invest in our digital technology to increase our capabilities and profitability.

“We had a grant from Warwickshire County Council, for which we were referred by Coventry & Warwickshire Growth Hub, towards a crankshaft grinder.

We previously had to sub-contract that element of the work and we were sometimes having to wait six months.”

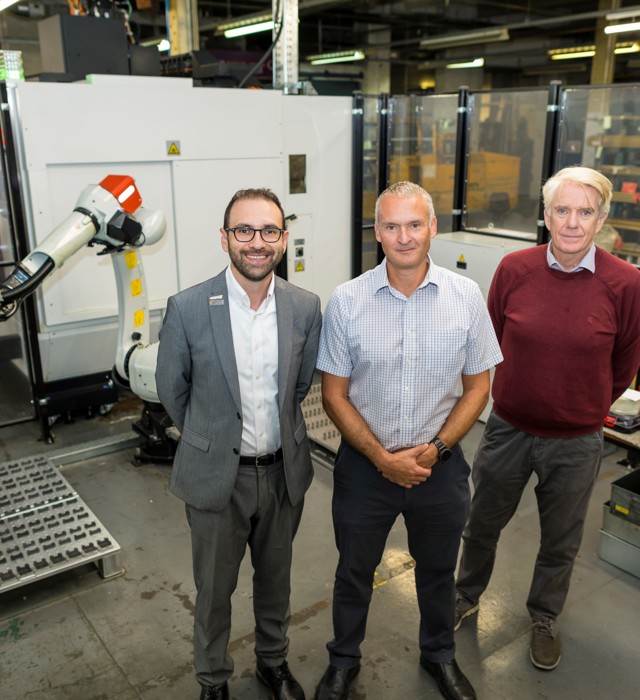

The Growth Hub then put the business in touch with Made Smarter West Midlands, and Digital Transformation Specialist, Paul Sullivan, visited their premises together with Fred Wray, Senior Advisor at the MTC, who are one of the strategic partners on the programme.

Yunus Khalifa, Digital Transformation Specialist, who now covers Coventry and Warwickshire for Made Smarter following the retirement of Paul Sullivan, said: “The initial application indicated D.A.R.L Engineering may not have been eligible based on the size and turnover of the business.

However, Paul went to visit and spotted there was a great opportunity for growth since they had undergone significant growth following the grant from Warwickshire County Council and had tripled their workload as a result of the new machine.

“It highlights the importance of the visits we make since Paul recognised their staff could be upskilled to improve the digital outputs of the business because it is really hard to find skilled staff.

“Digitalisation is ideal for younger members of staff because they develop ‘ownership’ of that part of the business, which gives them extra responsibility and increases their skills.”

D.A.R.L Engineering applied for a £20,000 grant from Made Smarter West Midlands, with the firm adding a further £67,000 to purchase a Hardinge XR600 5AX machine.

“We wanted to make the investment because of our workload,” Kim explained. “If one machine wasn’t working, we couldn’t fulfil our orders and we were getting so many orders coming in that there was too much work for one machine.

“The new machine manufactures components, and its larger table means we can also make Specialised Brake Callipers and cylinder heads amongst many other specialised components.”

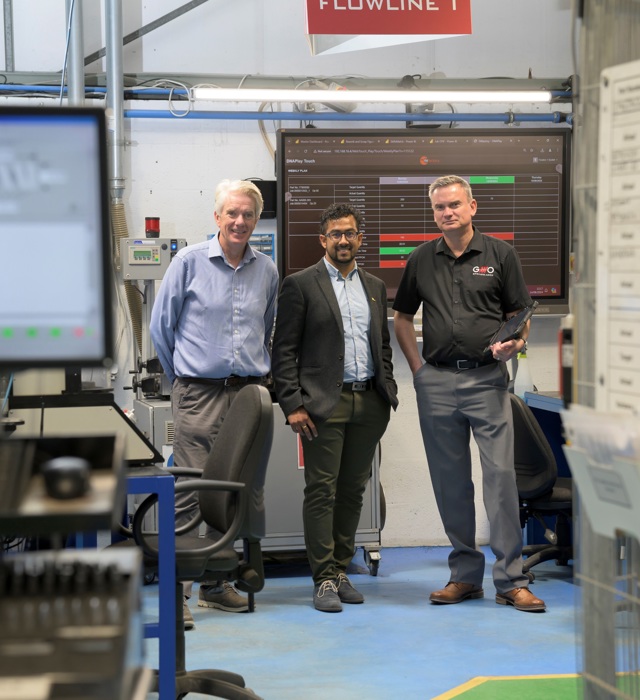

Fred Wray, of the MTC, said: “We supported Kim with the grant application towards investing in digital hardware to improve the business’s digital technology so that the two CNC machines would then be connected and would have remote programme availability.

“These machines can be monitored from Kim and Daren’s home and programmed externally.

“D.A.R.L Engineering is now looking to other digital projects, such as systems on the shop floor to capture data to improve their efficiency, particularly with repeat orders, which is key to maintaining their good reputation and securing further work.”

Both CNC milling machines are up-and-running which is beneficial particularly considering the quantity of its orders since the firm has increased its productivity. Kim explained: “We are a small family-run business, and the team has really impressed us with the way they have dealt with the digital changes.

“It also means we can give them more responsibility. Before, we always used to shut down for two weeks in the summer to go on holiday, but this year Adam and Ryan ran the business, which was great experience for them.”

Councillor Martin Watson, portfolio holder for Economy at Warwickshire County Council, said: “This is an excellent success story which reflects positive and sustainable growth in advanced engineering and manufacturing, one of our core sectors where we are focusing our resources and strengthening the county’s future economy.

Our grant played an important part of the company’s growth, enabling them to purchase the crankshaft grinder, turn a waiting list into ongoing business, and triple their workload.

“This then led to the Made Smarter support and now the company’s growth has really gathered momentum and they are offering employment opportunities to the younger job market.

“We’re delighted to have been part of the process and extend our best wishes to all at D.A.R.L whose hard work has made the most of the opportunity we helped to create."

The benefits of D.A.R.L Engineering increasing their digital capability led to the company winning the 2024 Made Smarter West Midlands Adoption Award category for Coventry and Warwickshire – much to their surprise!

“It was a total shock,” Kim said. “We were amazed to have been nominated and then shortlisted with two other businesses because we are much smaller. We thought we would go along to the awards ceremony and have a good night, but we were not expecting to win.”

D.A.R.L Engineering has started renting the next-door premises to take the total size of its units to 5,000 sq ft, to meet continuing demand.

“When the business was started in 2019, our turnover was £200,000 and we are confident we will reach £1 million in the next financial year,” Kim said. “We are investing in a further smaller Hardinge XR300 5AX machine which is half the size of the larger two CNC machines, so it is ideal to have another machine to produce smaller parts. It frees up the larger machine for further capacity on more complex parts.

“We’re also looking into running the machines when we’re not here. We’re looking at digital machine monitoring software so we can leave them running during the night and then switch them off at home.”

The former Mayor of the West Midlands, Andy Street, also visited their premises in December 2023 to see first-hand the scale of the positive impact Made Smarter has had on West Midlands manufacturing and engineering businesses.