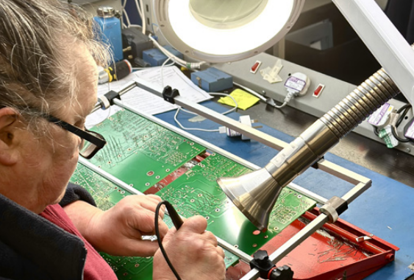

A leading manufacturer of electronics, LED lighting, fibre optics, and cable interconnect solutions, has accelerated its digital transformation with the help of Made Smarter.

Altimex, located in Chester, developed its digital strategy through Made Smarter’s tailored digital transformation workshop. Owner and Managing Director, Davinder Lotay, then took part in the Leading Digital Transformation (LDT) programme which empowered him with the vision, skills, and motivation to execute the transformation.

As a result the company’s operations are faster and more productive, fuelling growth by 10% this year.

Davinder said: “As a company, it’s easy to become isolated and blinkered. Made Smarter opened my eyes to the possibilities and inspired me to pursue digital transformation without fear, bringing my entire team along for the journey.”

Case Study - AltimexThe Made Smarter approach has been incredible.

It’s given us the confidence to embrace change and inspired us to keep improving the business.

Davinder Lotay Managing Director of Altimex

Altimex was founded in 1995 and has flourished through a combination of organic growth and strategic acquisitions.interconnect solutions.

Today, Altimex has grown into a £3 million business with a dedicated team of 23 employees.

With a strong history of adopting digital tools and technologies across both design and production, Altimex has seen notable success, particularly in the area of 3D printing.

However, the company has also encountered challenges, including difficulties in implementing an ERP system.

In 2023, the business engaged with Made Smarter looking for support.

The first step in Altimex’s journey was a digital transformation workshop, which included a deep dive into the company’s products, processes, and people, as well as an assessment of its digital readiness.

Ian Marshall, Digital Transformation Specialist, and Ruth Hailwood, Lead Organisational Development Specialist, visited the factory for the evaluation.

Davinder said: “Inviting someone into your business to critique it can be unsettling. However, what we learned was that we were on the right path with our digital transformation efforts, but we could benefit from additional support in leading that change.”

As a result, Davinder was invited to participate in Made Smarter’s Leading Digital Transformation programme, designed to equip digital leaders with the vision, skills, and drive needed to advance smarter manufacturing practices.

The programme, delivered over three months in collaboration with Manchester Metropolitan University, combines face-to-face workshops, online webinars, case studies showcasing technology in action, and a site visit to PrintCity, the university’s 3D additive and digital manufacturing centre.

Reflecting on the programme, Davinder said: “I came to it with a digital strategy that has transformed our business over the last 20 years through the use of digital tools, automation, 3D printing, and collaborative platforms. Through the programme, I had the opportunity to share our successes and challenges with other manufacturers, while also learning from their experiences. We’re all on the same journey.”

“This programme has highlighted the complexity of change management and reinforced the importance of a people-centric approach. Clear communication and transparency are crucial, and demonstrating the benefits of change to keep your workforce engaged is essential.”

One of the key outcomes of the LDT programme was that Davinder used the insights gained to reignite and successfully advance Altimex’s stalled ERP implementation.

“The ERP implementation had been attempted twice before, and both times it had failed,” explained Davinder. “The LDT programme gave me the opportunity to step back and assess why. I realised that our leadership approach had been too prescriptive and lacked inclusivity, and the team found the task of data input and cleansing too overwhelming,”

“As I participated in the Made Smarter workshops, I shared what I was learning with the team. This not only gave them confidence in our approach but also helped accelerate the ERP project. By adjusting my leadership style, empowering the team, and breaking the project into manageable phases, we were able to tackle it successfully.”

The results have been transformative for Altimex. With a single source of truth and enhanced data analysis capabilities, the company has identified bottlenecks and discovered efficiencies that have made operations faster and more productive.

Turnover is forecast to grow by 10% over the next year, and the team has expanded from 19 to 23, with new roles created as a result of opportunities uncovered through the ERP system.

Looking ahead, Altimex is now exploring the adoption of a Customer Relationship Management (CRM) system to further streamline operations.

Davinder said: “The Made Smarter approach has been incredible. It’s given us the confidence to embrace change and inspired us to keep improving the business.”