An aerospace engineering specialist has tripled in size and expanded into new international markets after investing in transformative scanning technologies with the support of Made Smarter.

Airframe Designs, based in Blackpool, used the purchase of a high-tech 3D laser scanner as a catalyst for a new 3D division, allowing the business to accurately scan and reverse engineer aircraft components, support damage assessments, and streamline design and manufacturing processes.

An upgraded scanner has now enabled the company to work on large-scale parts, including full airframe structures.

Case Study - Airframe DesignsThe technology and innovation that the scanner brings is game-changing. The support from Made Smarter has been fantastic and really accelerated our plans.

Jerrod Hartley, CEO, Airframe Designs

Founded in 2009, Airframe Designs started out offering structural analysis services to the aerospace industry. For the first decade, growth was steady, but it remained a tight-knit operation, led by CEO Jerrod Hartley.

By 2018, Jerrod brought in Chris Fleet to establish a new design department, taking the company’s first steps toward offering a more complete engineering service.

The COVID-19 pandemic hit Airframe Designs badly, like much of the civil aerospace sector. This prompted a strategic pivot. The team diversified into other aerospace areas and looked at how to build in manufacturing capability, particularly in additive manufacturing.

In 2022 Garry Sellick was brought in to oversee that division.

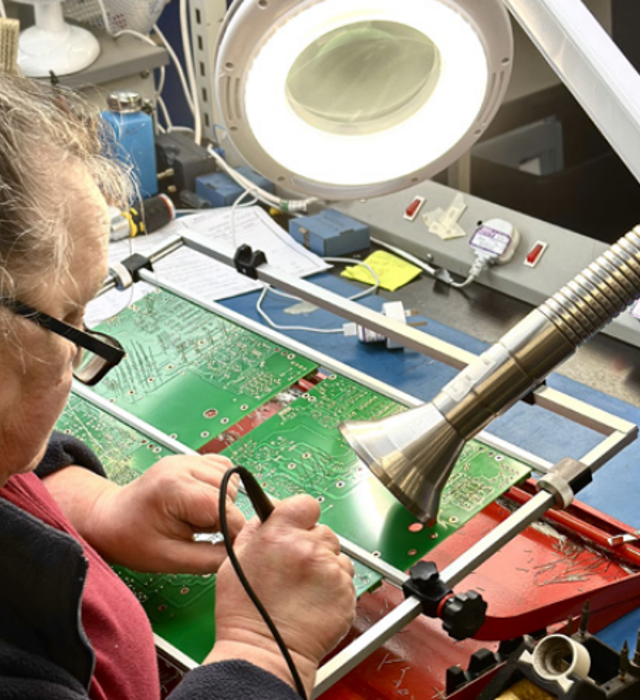

Garry Sellick, Additive Manufacturing Manager, said: “The manufacturing division didn’t exist yet in any real sense. There were no 3D printers, no equipment, no defined process. Reverse engineering projects were starting to come in, but we were doing them the old-school way: rulers, micrometers, calipers, and a bit of guesswork. For complex geometry and critical surfaces, that just wasn’t going to cut it. We needed proper scanning capability. That’s when the opportunity came up to integrate 3D scanning technology to support our growing ambitions.”

After engaging with Made Smarter, the business secured a £20,000 grant to invest in a high-tech 3D laser scanner capable of handling small parts up to a metre in size. This technology enabled the precise capture of geometrical data and seamless integration across the company’s design, analysis, and manufacturing teams - as well as with its customers.

This initial investment laid the foundation for the company’s dedicated 3D division, which has since expanded to include a second scanner equipped with a photogrammetry package. This upgrade significantly enhances accuracy on large-scale components, including entire aircraft structures.

Today, the business uses both scanners: the original for small, intricate jobs, and the newer system for larger or more complex geometries.

Since the introduction of scanning technology, the business has been transformed.

It now offers a turnkey service - design, analysis, manufacturing, and reverse engineering.

The scanner has been a gateway to winning work across all those areas.

The company has tripled in size since 2022, growing to 33 employees, with plans to grow by another 20 in the next two years.

The manufacturing division now employs five, including two apprentices, all of whom have been upskilled in advanced scanning and manufacturing technologies.

By adopting more efficient digital and additive processes, the business has increased the number of parts it manufactures from none to 100s of parts per annum currently, with the aim of achieving +1,500 parts over the next five years, alongside significant savings of CO2 over the same period.

The company has taken on six engineering apprentices which forms part of a commitment to “growing its own” and addressing the gap in mid-career engineering talent in the aerospace sector.

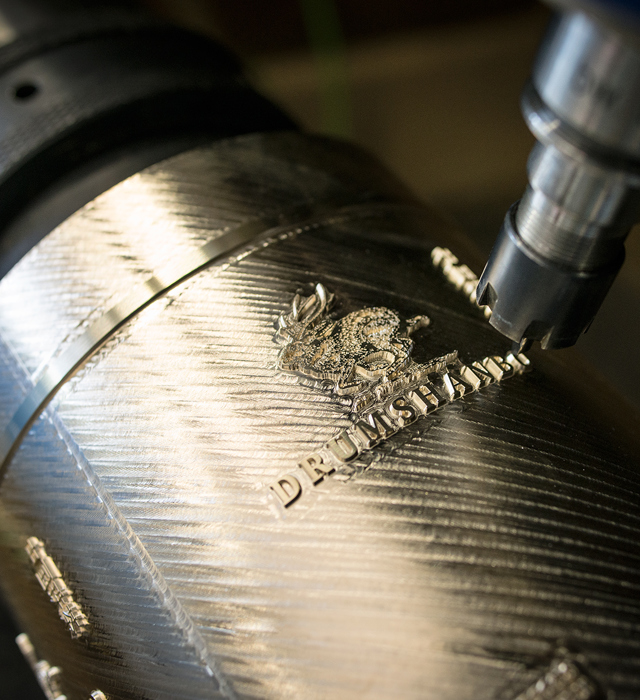

The technology has unlocked new services with the ability to reverse engineer complex tooling for composite layups, which would have not been possible using traditional techniques.

Accurate 3D scans of complex structural features and geometry are also able to support damage assessments on airframe structures. This is an area where traditional ultrasonic methods fail. Scanning allows the company to recreate complex digital-twin geometry and calculate material loss or shape change.

Jerrod said: “It’s not just about better results - it’s about opening doors. Every scanning job tends to lead to design and analysis work. Without the scanner, we wouldn’t be in the position we are now.”

Airframe Design is now looking to expand its additive manufacturing capabilities and engineering services, as well as develop its own products.

It is also just finalising a major six-month project with a large Middle Eastern carrier which aims to reverse engineer and manufacture broken or worn cabin interior aircraft parts which are no longer supported by OEMs or where it is difficult to source parts quickly and affordably.