Sculpteo’s 2022 “The State of 3D Printing” report emphasises the growth of 3D printing in businesses to try to meet sustainability ambitions. From reducing waste and materials to increasing recycling, 3D printing will help organisations satisfy their own objectives and reach the UK’s 2050 aim of net zero.

Join me, Claire Scott – Industrial Technology Adviser – as I discuss what 3D printing is, how it can help sustainability, and highlight Sculpteo’s key findings from their report.

What is 3D printing?

3D printing – also known as Additive Manufacturing (AM) – is a set technology that creates products by depositing material layer by layer. There are many benefits, including greater design freedom, lessened time to market or production, on-demand manufacturing, reduced inventory holding, and cuts to waste and costs of production.

Perhaps the biggest draw of AM is its role in sustainability. In fact, 41% of users agree that AM is a useful tool to help them achieve green objectives. What’s more, increasing AM recycling options mean more and more businesses can see the value in AM.

What can you use 3D printing for?

On-demand tooling is just one of the ways manufacturers use 3D printing to improve their processes.

Sculpteo’s report found that 61% of businesses think that it boosts sustainability (as shown in figure 1). But it’s not enough to believe this – we need to translate this into a reality and take action on using additive manufacturing.

On-demand 3D printed tools have many uses – namely, holding parts during manufacturing processes. Lead time can be cut from weeks to days. And once you have the digital file, it’s quick and easy to create and replace one.

What are the benefits of 3D-printed tooling?

Cost savings aren’t the only benefits of 3D printed tools. Additive manufacturing also has a positive influence on an organisation’s carbon footprint. There’s less material usage and no delivery impact with tools produced on-site. This has the potential to significantly reduce your carbon footprint – depending on where you currently import your tools from.

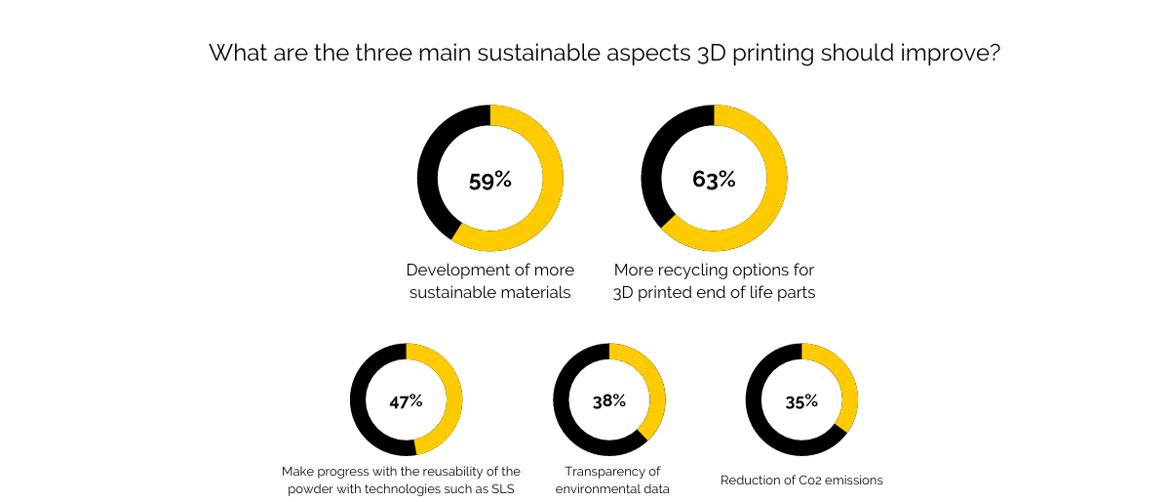

And the sustainability of 3D printed tooling doesn’t stop there. Additive manufacturing. tools have strong recycling potential – a big concern for the industry, as 63% of survey respondents feel that there need to be more recycling options available (as illustrated by Figure 2).

What action is the 3D printing community taking?

As I’ve made clear, additive manufacturing. is very beneficial for sustainability. In an ideal world, we’d adopt the technology more quickly and take advantage of related innovation to reach net zero sooner. Thankfully, there’s a community who are helping to do so, with specific organisations leading in the efforts. For example, Manchester Metropolitan University is running the TRANSFORM-CE research programme.

The project seeks to turn single-use plastic waste back into raw plastic material used for additive manufacturing. Find out more about how businesses can engage with the programme.

Support with 3D printing finance

The report highlights that despite 89% seeing 3D printing as a strength or competitive advantage, they struggle to access the budget to purchase the necessary equipment. Financing remains the biggest challenge. That’s where Made Smarter comes in.

If you’re a maker or creator looking to action sustainability goals with 3D printing or other industrial digital technologies, then Made Smarter can support you through a guided adoption process and potentially a grant. The first step is to register today to start your digital journey.