In manufacturing, every second counts. Even small delays or mistakes can lead to wasted time, higher costs, and missed opportunities.

That’s why more manufacturers are turning to real-time data to help them make better decisions, faster.

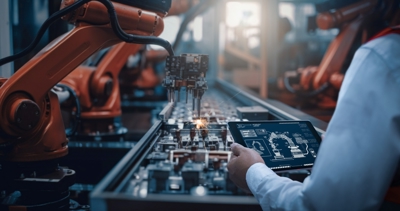

Imagine having up-to-the-minute information about everything happening in your factory, from machine performance and energy use to staff productivity and stock levels. With digital tools that provide real-time data, you can spot issues as soon as they arise, make adjustments immediately and optimise your operations like never before.

Making decisions faster and smarter

Real-time data gives manufacturers a clear view of what’s happening on the factory floor. For example, if a machine starts to slow down or malfunction, you can see it straight away and decide whether to perform maintenance before it breaks down completely. This way, you avoid unexpected downtime and keep production running smoothly.

Similarly, if there’s a delay in the supply chain, you can quickly assess the impact on your production schedule and make informed decisions to minimise disruption. Real-time data helps you respond to challenges in the moment, rather than discovering problems after they’ve already affected your bottom line.

Optimising processes and reducing waste

Data-driven insights can also reveal where inefficiencies and waste are occurring. By analysing real-time information, manufacturers can pinpoint areas for improvement – whether it’s reducing energy consumption, improving machine performance, or refining production workflows. For example, by monitoring how long each stage of production takes, you might identify bottlenecks that slow down your overall process. Once identified, you can take action to streamline operations and increase output.

Digital tools that provide real-time data can also help you optimise your inventory. Instead of overproducing or running out of stock, you can monitor demand and adjust production levels accordingly. This means less waste, lower costs, and a more efficient use of resources.

Seeing the bigger picture with real-time data

With access to accurate, up-to-date information, manufacturers can make more informed decisions that have a direct impact on productivity and profitability. Real-time data allows you to understand how each part of your operation is performing and how they affect one another. You get a clearer picture of your entire production process and can plan more effectively for the future.

Get ready for the new Made Smarter East Midlands programme

The Made Smarter East Midlands programme is here to help manufacturers utilise the power of digital tools like real-time data. Due to the programme’s huge success, it is being extended and expanded in April 2025, with increased funding and a wider range of support. Over 200 manufacturing businesses across the East Midlands will benefit, with a focus on boosting workforce skills and improving decision-making through technology.

Don’t miss your chance to be part of this exciting new programme. Register your interest today to ensure you’re ready to make your factory smarter, more efficient, and better equipped to handle the challenges of the future.