Will Kinghorn, Automation and Robotics Specialist for the Made Smarter Adoption Programme, looks at how automation can ease pressure on manufacturers, boost productivity, and create space for teams to focus on what they do best.

Picture this: it’s the middle of a busy production run. Orders are stacking up, but your team is already stretched. A machine operator is off sick, and staff are working flat out to keep up. Every small delay feels like it directly affects customer deliveries. Sound familiar?

This is the reality for many SME manufacturers today. The latest Make UK / BDO Manufacturing Outlook Q3 2025 report shows manufacturing activity is bouncing back – output is rising, overseas orders are strong, and investment is flowing again. But the sector is also facing a crunch: rising costs and nearly 46,000 vacancies unfilled across UK manufacturing.

That’s where automation comes in – not as a replacement for people, but as a powerful tool to relieve pressure, unlock productivity, and make life easier on the factory floor.

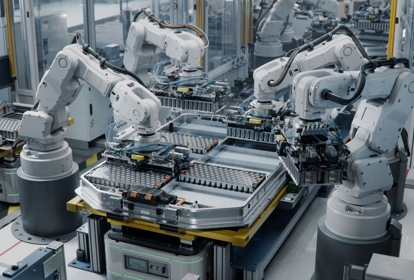

What automation looks like in practice

Automation is simply about getting machines to do the repetitive, time-consuming jobs so your people can focus on what they do best.

- In some factories, that might be automating low skilled tasks such as cutting, painting, or finishing - using machines to allow skilled operators to focus on complex tasks,

- In others, it’s about higher volume, repetitive tasks, like packing or labelling.

- And for more complex work, automation supports mass customisation, for example pairing CNC machines with automated handling and inspection systems to deliver variety without sacrificing speed.

The benefits manufacturers are seeing

The gains aren’t just about speed. Manufacturers adopting automation are seeing:

- Higher productivity, with staff freed up for more valuable and engaging work.

- Better health and safety, by removing heavy or hazardous tasks.

- Shorter lead times and cycle times, keeping customers happy.

- Reduced waste, thanks to more efficient use of materials.

A real-world example: Firstplay Dietary Foods

Take Firstplay Dietary Foods, a manufacturer that relied on manual packing. Their process was slow, labour-intensive, and held back growth.

With Made Smarter’s support, they invested in a powder packaging machine – introducing automation into their production line. The result? Faster, more consistent packing, less strain on staff, and more time for their team to focus on higher-value activities.

This is automation in action: solving real challenges, delivering immediate impact, and setting businesses up for long-term success.

How Made Smarter can help you

Our role is to make automation achievable. We’ll work with you to understand your products, processes, and people – listening to voices from across the factory floor. Then we’ll help you cut through the jargon and identify the solutions that will make the biggest difference.

From tailored advice and skills support to funding opportunities, Made Smarter is here to help you take the next step on your digital journey.

Now is the time to explore where automation could free up your team, strengthen your processes, and help you do more with what you already have.

About the Author

Will is the automation and robotics specialist for the Made Smarter Adoption Programme in the North West, where he advises and supports manufacturing companies with the adoption of new technologies. Will is a chartered manufacturing engineer with the IMechE, and his background is in the aerospace industry where he developed and implemented new manufacturing techniques including automation, robotics, advanced machining, inspection, and welding. He is the author of Digital Transformation in Your Manufacturing Business - A Made Smarter Guide.