Before I joined the Made Smarter team, I worked in what was traditionally seen as the environmental sector. Many have asked why I left it behind – my response has always been ‘I haven’t’!

Environmentalism isn’t just a job responsibility or an auditable certification, it’s a lens through which you see the world. From my perspective, Made Smarter is an environmental project that’s helping a resource-intensive sector boost sustainability by improving efficiency with technology – and it’s hugely exciting to be a part of.

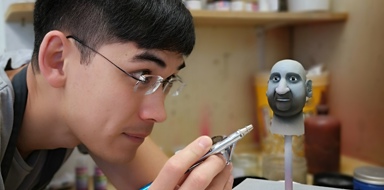

There are “some amazing things beginning to break” within AM, one of the digital technologies identified in the Made Smarter Review. Here’s four ways it’s super environmentally friendly…