Made Smarter has empowered 125 digital leaders with the vision, skills and drive to pursue smarter manufacturing through its two innovative leadership programmes.

The participants hail from across the spectrum of the manufacturing workforce, from managers to production operatives.

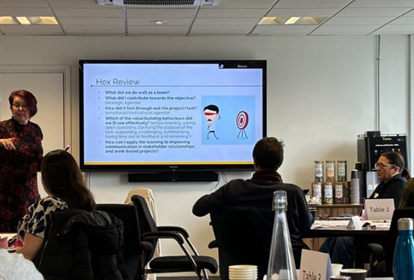

Made Smarter, a government-funded industry-led initiative to increase technology adoption among SME manufacturers, offers funded access to its Leading Digital Transformation (LDT) programme and Leading Change for Digital Champions (LCDC) programmes.

LDT, which is delivered over three months with Manchester Metropolitan University (Manchester Met), blends face-to-face workshops, online webinars, case studies to see technology in action, and a site visit to PrintCity, Manchester Met’s 3D additive and digital manufacturing centre. Since last year, the programme has turned 34 delegates into digitally-informed, empowered leaders, armed with a bespoke digitalisation strategy.

LCDC is delivered using a bite-size, blended approach consisting of two face-to-face workshops, online coaching, a site visit to an SME manufacturer to see the impact of digital change first-hand, as well as a chance to see the latest digital technologies at an Amazon fulfilment centre. The programme has so far created a network of 29 advocates to guide others and support the impactful and lasting changes digital technologies will bring.

This is in addition to the 62 business leaders equipped with new digital skills through Made Smarter’s trailblazing leadership initiative run between 2019 and 2023.

Manufacturers across the North West are now being encouraged to register their interest for the next series of programmes.

Commenting on her experience, Alison Brooks, Business Manager at Massey & Harris, a playground equipment manufacturer, based in Stockport, said: “The belief and confidence I have walked away with, both professionally and personally, is quite something. The programme was well led, engaging, full of useful information, and a real source for inspiration.

“Any fears I had about the programme being too technical disappeared from the first session and I was hooked. I was able to quickly ascertain where we were as a company, why we had previously failed in leading change, what we needed to do, when, and how. I was also able to implement changes immediately, improving communications and increasing the buy-in for the changes in the pipeline.

“I also really benefited from learning from her peers and visiting their factories. Although we are all at different stages, it is comforting that we share the challenges. The peer learning forums were an added bonus to discuss and share business issues and good practice, the other delegates are now regular contacts - and friends.

Neil Kershaw, Research & Development Chemist at Colour Synthesis Solutions, a specialist manufacturer of dyes and pigments, based in Manchester, said: “We have been on an incredible digitalisation journey over the last decade investing in ERP, document control and lab technologies to grow our business. Our next focus is integrating our systems and operations.

“What I took away from the programme was that change has to be handled delicately. People fear change, so it is important that you make it easier and intuitive for everyone. This programme enhanced my skills in understanding and managing change.”

Since launching in 2019 Made Smarter has supported 2,500 manufacturers in the North West to access expert, impartial technology advice, digital transformation workshops to help take that first step to transform a business, and support with technology adoption projects. It has also supported 284 businesses with skills and leadership advice and training.

Ruth Hailwood, Made Smarter's Organisation and Workforce Development Specialist Adviser, said: “Made Smarter has taken a people-first approach to helping SME manufacturers adopt technology tools to take their businesses forward. Technology tools bring change to the way day to day work is done and this change needs to be led to make sure the people in the business are ready to use these tools to maximise the benefits for the business and realise the potential of their people.

“Our Leading Digital Transformation programme and Leading Change for Digital Champions programmes work hand in hand to support SME manufacturers to take their entire organisation and people through digital transformation successfully and maximise the opportunities for their business.

“Ultimately, accelerating changes to leadership and skills within the industry, especially with SMEs, will make the biggest difference to achieving successful digital transformation and reaping the benefits for UK manufacturing economically, socially and environmentally.”

To learn more about how Made Smarter supports SME manufacturers to become digital leaders download our white paper.