Conduct an initial assessment of the current state of the digital transformation and other process targets within your business and the systems that support them. Are you achieving your KPI’s against plan? Can you still achieve more with what you have? Are technical and business skills holding you back?

According to West Midlands Made Smarter Industrial Digital Technology Specialist, Barry Jones, the answer is a most definite ‘yes.’

“Industry 4.0 technologies have been designed specifically to help UK industry be at the forefront of smart manufacturing, optimising performance for businesses and their customers.”

Register now to find out how technology can change your manufacturingWhat are digital technologies?

The Digital Technology era brought about by information technology and tools like artificial intelligence (AI) and robotics now requires us to think about how the advent of this wave of exponential change, (the drive to machine learning and smart manufacturing) will require companies to look to the future with a different perspective. The harnessing of the information provided by these technologies represents a significant underused asset to your business.

UK businesses, regardless of industry have become technology organisations. Information is cascading down upon businesses in unprecedented volumes and formats, challenging our traditional concepts of how information, technology and people must work together; often necessitating changes to “the way we’ve always done things.”

These changes will undoubtedly create challenges at the cultural and operational level of a businesses as the need to consider INNOVATION – CUSTOMER- COMPETITOR – EMPLOYEE expectations are key going forward.

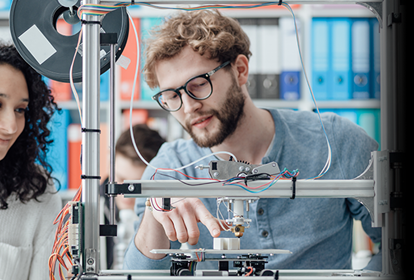

Staff retention will be critical, and possible up-skilling of existing staff will play a major part in the success of any project. The future will be to attract young engineers whose expectation will be driven towards those companies who are on the technology ladder. It’s likely, given the pace of technology change that Industry 5.0 will be upon us sooner than we think and having skilled engineers will be critical.

To drive manufacturing performance, we must align resources, energy and efficiency, manufacturing operations will have the potential to reduce inventory, identify costly production gaps, lower energy and waste and gain an improved understanding into throughput into critical processes, enabling you to unlock significant opportunities for more efficiencies towards Lean and Smart Manufacturing and Continuous Improvement (CI).

We know the adoption of these technologies hold huge potential for manufacturers but understand it can feel like a lengthy and costly process. Could you advance and accelerate your business through technology adoption, but don’t know where to start or how? Join the Made Smarter programme NOW to help you start that journey.